Description

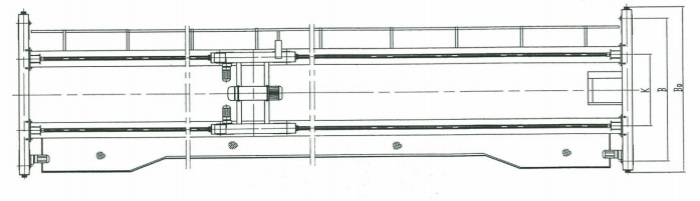

LH type electric hoist bridge crane uses electric hoist as lifting mechanism, and the bridge frame adopts semi-deviated box girder. The operating mechanism of the trolley is divided into two modes: drive device transmission and “three-in-one” transmission according to product specifications and user requirements.. It has the advantages of compact external dimensions, low building clearance height, light self weight, and low wheel pressure. It is an economical, practical, reliable, and easy to operate lifting equipment. The LH type hoist double beam crane is mainly suitable for the operation, assembly, maintenance, and loading and unloading operations of machinery manufacturing workshops, warehouses, material yards, power stations, etc. It can complete various transportation, assembly, maintenance, and loading and unloading operations.

Working Condition

- Metal structures and mechanical parts should have sufficient strength, stiffness and buckling resistance.

- It is required that parts and metal structures are not damaged after being loaded. For parts such as steel wire ropes with complex stress states, static strength calculations are usually carried out based on the main load and main deformation form, and a higher safety factor is used. It must also be required that the deformation of the component under the action of the load is within the allowable range, that is, There should be sufficient stiffness. Second, the whole machine must have the necessary stability against overturning.

- The prime mover has the power to meet the operating performance requirements, and the braking device should provide the necessary braking torque.

Features

FEATURE 1

The LH electric hoist bridge crane is suitable for working in working levels A3 to A4, working environments with temperatures ranging from -25 ℃ to+40 ℃, and environments without flammable, explosive, or corrosive media.

FEATURE 2

The lifting capacity is 3-63 tons, with a span of 7.5-31.5 meters. The power supply of the crane is three-phase AC, with a rated frequency of 50Hz or 60Hz.

FEATURE 3

The rated voltage is between 220V and 660V. The upper limit of allowable voltage fluctuations on electric motors and appliances is+10% of the rated voltage, and the lower limit (during peak voltage) is -15% of the rated voltage. The internal voltage loss of the crane shall not exceed 3%.

Technical Data

| Capacity | t | 3~20 | |

| Span | m | 10.5-31.5 | |

| Lifting height | m | 6~18 | |

| Speed | Lifting | m/min | 8,8/0.8, 7,7/0.7 3.5,3.5/0.35 |

| Cross travel | m/min | 20,30 | |

| Electric hoist | type | CD/MD/HC | |

| Working duty | A3, A4 | ||

| Power supply | AC | 380V/50HZ/3P or Customized | |

Spare Parts

Main beam

The main beam is a box beam or H-beam structure, welded and formed from steel plates. The steel plate material is domestic steel (Q235B). The vertical winding is in accordance with Chinese national standards. All steel plates are subjected to shot blasting pre-treatment to achieve Sa2.5 level standardization. Before welding, the steel plates are carefully inspected and cleaned, usually by automatic welding machines (MIG or semi-automatic welding).

End beam

End beam is a supporting structure designed for lifting machinery, usually located at both ends of the crane, and its function is to provide stable support and balance for the crane. Cranes need to bear enormous weight and inertial forces during operation. Without the support of end beams, the crane is prone to imbalance or even overturning. Therefore, the role of the crane end beam cannot be ignored, as it is one of the key components for the safe operation of the crane.

Electric hoist

The electric hoist will do dynamic and static load tests, as well as ascending and descending pressure tests. The baking paint process is used to enhance the adhesion of the paint film and improve the appearance quality. The assembly line ensures product quality.

Crane remote control

Industrial wireless remote control is a remote wireless remote control device specifically used to control construction machinery or industrial equipment.

Crane control box

The surface of the control box has undergone anti-corrosion treatment Reasonable layout for easy maintenance Protection level IP55 Environmental temperature:<45 ° C, humidity<90%.