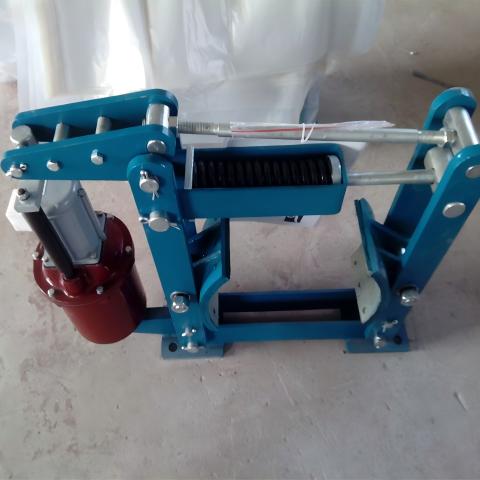

Description

Due to the periodic and intermittent working characteristics of cranes, various working mechanisms are often in frequent starting and braking states. Brakes have become an indispensable component of the power driven crane mechanisms. They are not only the control device for mechanism operation, but also the safety device to ensure crane operation. Whether the brake is intact and reliable is the focus of safety inspection. The crane brake is installed on the shaft of the electric motor, used to brake the operation of the electric motor, so that its operation or lifting mechanism can accurately and reliably stop at the predetermined position.

Working Condition

1.Environmental temperature -20 ℃~+50 ℃

2.The relative temperature of the air shall not exceed 90%

3.The surrounding environment must not contain flammable, explosive, or corrosive gases.

4.The altitude of the location of use complies with GB755-2000

Features

FEATURE 1

Supporting effect: Keep the original stationary object in a stationary state. For example, in the lifting mechanism, keep the lifting weight stationary in the air; In the slewing mechanism of a boom crane, keep the boom in a certain position and remain stationary; It has the function of windproof and anti-skid for outdoor cranes.

FEATURE 2

Stopping effect: The kinetic energy of the moving part is consumed and converted into frictional heat energy through the friction pair, causing the mechanism to quickly stop moving within a certain time or stroke. For example, the braking of various mechanisms in motion.

FEATURE 3

Falling weight effect: The braking force and gravity balance, causing the moving body to descend at a stable speed. For example, the downhill speed of a car crane.

Technical Data

| Type | D | Braking torque (KN·m) | A | b | D | D1 | d | E | F | Weight(kg) |

| 160/18 | 160 | 80-140 | 345 | 65 | 160 | 137 | 14 | 157 | 90 | 25 |

| 160/25 | 112-180 | 354 | 154 | 37 | ||||||

| 200/18 | 200 | 100-125 | 346 | 80 | 200 | 137 | 14 | 190 | 90 | 28 |

| 200/25 | 112-225 | 379 | 154 | 43 | ||||||

| 250/25 | 250 | 140-225 | 408 | 100 | 250 | 154 | 18 | 220 | 100 | 58 |

| 315/45 | 250-400 | 420 | 178 | 70 | ||||||

| 315/25 | 315 | 180-280 | 440 | 125 | 315 | 154 | 18 | 247 | 110 | 74 |

| 315/45 | 315-630 | 522 | 178 | 78 | ||||||

| 315/90 | 630-1250 | 538 | 210 | 147 |

Compliant with standards

The installation dimensions of the YWZB series electric hydraulic drum brake comply with the JB/ZQ4388-1997 standard.